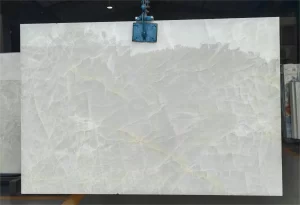

Pietra Gray Marble Slabs

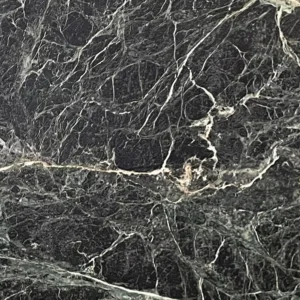

A stunning modern marble with a consistent, vivid gray, Pietra Gray Marble Slabs is gorgeous. This marble has stunning veins all over the slabs and is made up of charcoal gray tones. It is the perfect stone for stylish, contemporary floors. Pietra Gray marble is a terrific option for countertops and is ideal for living spaces like kitchens and bathrooms.

The utilization of this natural stone design is widespread.

The first natural stone quarried in Iran is Pietra Grey Marble Slabs. The material is one of the most opulent stones used in residential projects, hotels, pubs, etc. for interior and external design because of the ideal colors and mix of white and black. Regarding the unique technical features of pietra grey marble, it is possible to carry out finishing in a wide range of price ranges while preserving the stone’s natural beauty.

Pietra Gray Marble Slabs is a kind of dark grey with white quartz features populer marble quarried in Iran.

Usage: Pietra Gray Marble is especially good for Building stone,countertops, sinks, monuments, pool coping, sills, ornamental stone, interior, exterior, wall, floor , paving and other design projects.

Additional Names:Pietra Gray Marble also called Persian Grey Marble,Grey Pietra Marble,Pietra Grey Marble,Grey Crystal Marble,Pietra Grigio Marble,Graphite Grey Marble,Petra Gray,Persian Nero Marquina Marble,Persian Marquina Black Marble,Shakespeare Gray Marble,Shakespeare Grey,Shakespeare Ashes .

Finishing Surface: Pietra Gray Marble can be processed into Polished, Sawn Cut, Sanded, Rockfaced, Sandblasted, Tumbled and so on.

Material | Pietra Gray Marble Slabs | ||

| Surface Finish | Polished,Honed, Antique,Acid-wash, Mushroom, Water-repellent, Flamed,etc. | ||

| Belows are common sizes, customer’s design are available | |||

| Common sizes, | Slabs | Talla | 1800(up) x 600(up)mm 2400(up) x 1200(up)mm 2800(up) x 1500(up)mm etc |

| Thk | 15mm, 18mm, 20mm, 25mm, 30mm, etc | ||

| Tiles | Talla | 305 x 305mm or 12” x 12” 400 x 400mm or 16” x 16” 457 x 457mm or 18” x 18” 600 x 600mm or 24” x 24” etc | |

| Thk | 10mm,12mm,15mm,18mm,20mm,2.5mm,30mm, etc | ||

| Countertops | Talla | 96″ x 26″, 76″x36″, 98”x26″, 108″ x 26″ | |

Thk | 3/4″, 3/8″, 1/2” | ||

| Vanity Tops | Talla | 25″x22″ , 31″x22″, 37”x22″ , 49”x22”, 60” x22” | |

| Thk | 3/4″, 3/8″, 1/2” | ||

| Edge Style | bull nose, ogee, bevel, eased, polish, etc | ||

| Packing | 1) Tiles & cut to size in Fumigated wooden crates. inside will cover by foamed plastics (polystyrene). 2) Slab in fumigated wooden bundle. | ||

| Usage | For internal and external decoration and construction. wall panel, floor tile, stairs, paving, wall cladding, countertop, vanity are available. | ||

| Quality Standard | 1) Polished degree 80°- 100°. 2) Thk tolerance : -/+0.5mm for countertop and big slab; -/+1mm for tile 3) Surface flatness tolerence: +/-0.3mm 4) Diagonal tolerance : +/-1mm. | ||

Pietra Gray Marble Slabs Picture

Our advantages

1. ODM and OEM services are offered.

2. Factory direct sales at highly competitive prices.

3. Strong Quality Assurance. Before shipping, quality is checked three times.

4. We promise that the samples and finished goods will meet your standards.

5. All samples and orders from clients would be kept private and recorded. Customers can easily and satisfactorily place new orders.

Quality Control

Automatic detection and manual inspection are both part of our quality control system, which we’ve implemented using cutting-edge international technology.We have a QC team with more than 20 members who have experience. To guarantee that the product is safe within the container, they will meticulously check the stone’s quality and specifications piece by piece, watching every stage of production till packaging is complete.

Quality details

1) 90 degrees or above for polished degree.

2) +/-0.5mm tolerance for thickness

3) +/-1mm for the diagonal tolerance.

4) Tolerance for surface flatness: +/-0.3mm.

5) Infrared-ray cutting machine with precise tolerance of +/-0.5mm for adjacent edge verticality.

6) Before packing, our QC checks each item carefully piece by piece.