There are many surface treatment methods of marble. From the perspective of multiple dimensions such as non -slip, dirt resistance, easy cleaning and collision, common marble surface treatment methods can be roughly divided into the following four categories.

1. The most conventional surface treatment, such as polishing surface, matte surface, etc.

- The polishing surface refers to the decorative surface made by polishing the flat plates for rough, finely grinding, fine grinding, and polishing powder and polishing agent. This surface is bright like mirrors, colorful colors, few pores and small.

- The matte surface refers to less polishing the surface, resin abrasive, etc. on the surface.

2. Non-slip surface treatment, such as surface pickles, fire burning, cloth pattern, water spray, litchi, pineapple, etc.

- Pickle surface is to achieve the visual effect by using strong acid corrosion of the surface of the stone. The treated stone will have small corrosion marks on the surface.

- Burning surface refer to the thick surface processed on the surface of the stone with high temperature flames.

- Surface of cloth pattern is to treat the surface of the stone into cloth texture, so that the texture of the stone can be retained, and the texture of the wallpaper can be imitated, giving a sense of wall cloth.

- Washing surface is to wash the surface of the stone with a water knife machine, showing unevenness, but the surface is smooth and angular, which is similar to the pickled surface, but the surface color is close to the light surface, which is slightly deeper than the sour facial washing and the water absorption rate is less.

- Litchi surface is made of hammer with a shape such as litchi leather on the surface of the granite. After treatment, the surface of the stone will form a rough surface like lychee leather, which is uneven.

- The surface of pineapple is to process the surface of the stone more uneven than the litchi surface and the grain feeling. Its material texture is exactly the opposite of the water washing. The uneven feeling is weak and the grainy feels.

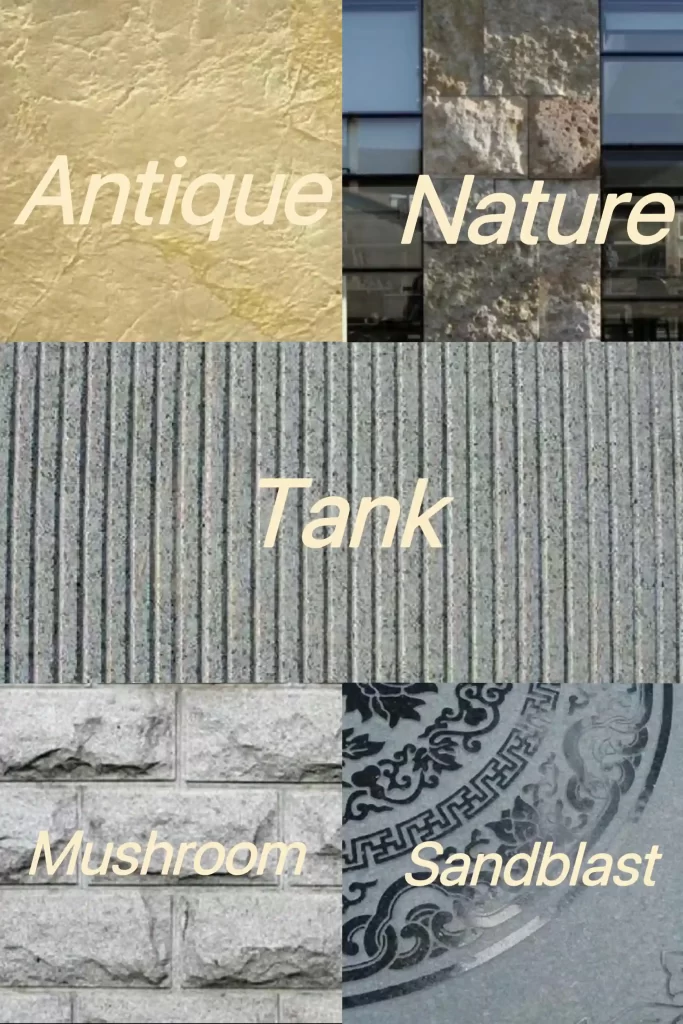

3. Decorative surface treatment, such as antique surface, slidd surface, mushroom surface, natural surface, sandblast surface, etc.

- The antique surface are to eliminate the characteristics of the thorns on the surface of the fire surface. After the stone is burned with fire first, it is brushed 3-6 times with a steel, which is the antique surface.

- The slot surface is also known as “pulling gap” or “drawing”. This is a groove of a certain depth and width on the surface of the stone. Usually, the straight wire groove is used.

- The mushroom surface refers to the board with a chisel and a hammer on the surface of the stone on the surface of the stone.

- natural surface, it is commonly known as a clear break and a cracking surface. It is to use machinery to split a piece of stone from the middle.

- Sand spraying surface. Now the process is generally implemented through the stone sandblast machine. It can adjust the size and uniformity of the required airflow according to the stone hardness. This processing method can make the stone have a good non-slip function.

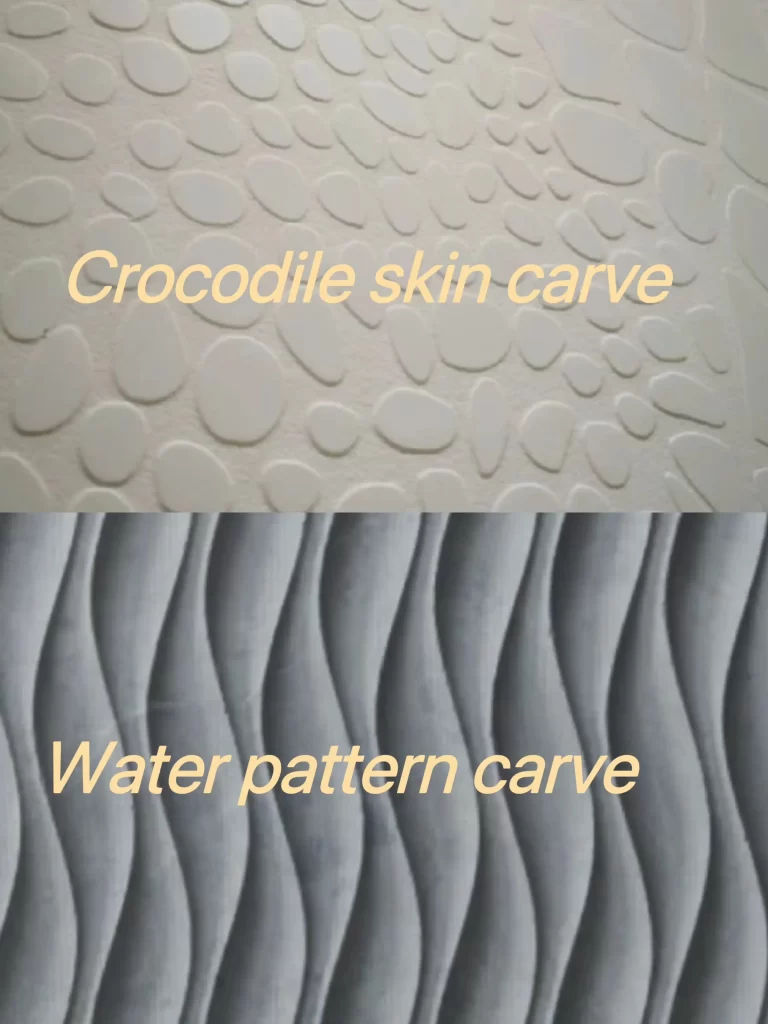

4. Sculpture and special surface treatment, as long as you can think of surface texture, such as crocodile leather carving, water pattern carving, etc.

As long as you can think of the surface texture, you can achieve it through the form of the carved version. The decorative effect of marble carving and special surface treatment is very beautiful and excellent.

Different stone plate surface processing can correspond to different customer needs. The characteristics of stone are suitable for processing, strong plasticity, and good decorative effect.